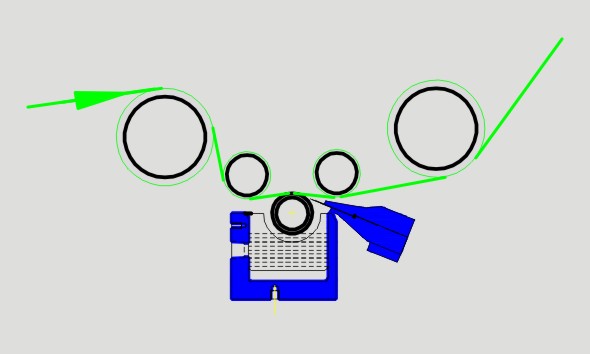

微凹版涂布

特點Features

該裝置體現了我公司先進的技術,目前在國內制造涂布裝備行業處于絕對領先地位,每個細節都體現了該裝置的“精準”,從輥的調節到每個部位的調節都做到了“μm”的級別The device shows our company's advanced technology, at present in domestic manufacturing coating equipment industry keep the absolute leading position, each part reflects the "precision" of the device, from the adjustment of the roller to the regulation of every part are achieved “μm" level

主要性能MainPerformance

1. 涂布輥 精密微凹版涂布輥1) 傳動采用精密無間隙減速機與伺服馬達驅動

2) 采用無齒隙精密聯軸器,拆裝非常方便

2. 涂布壓輥:壓輥的精確調節及精密定位,而且每一格嚴格定位2μm

1) 精密自鎖手輪+無齒隙減速機

2) 不銹鋼寬幅導軌

3) 精密進口磨砂鋁輥

4) 所有件耐溶劑、油脂等化學溶劑

3. 刮刀系統

1) 角度、位移采用精準調節裝置

2) 精密滑臺

4. 膠水循環

1) 高強度鋁合金壓鑄而成變形小 表面噴涂防粘材料

2) 采用無脈動泵供料系統

5. 控制部分

1) 單獨觸摸屏操作

2) 驅動可以手動、自動控制

1. Coating roller: precision micro gravure roller

1) transmission adopts precision no clearance speed reducerand servo motor drive

2) no backlash precision coupling, easy for install and

dismounting

2. The coating impression roller: accurate adjustment and precise positioning,

And every strict localization 2 μm

1) precision self-locking handwheel + no backlash reducer

2) stainless steel wide guide rail

3) precision imported brushed aluminium roll

4) resistance all the chemical solvents such as to solvent, grease

3. Doctor Chamber system

1) Angle and displacement using precise adjusting device

2) the precise sliding table

4. Glue loop

1) small deformation due to high strength aluminum alloy die

casting, surface coating non-adhesive material

2) Smooth flow pump feeding system

5. Control part

1) Individual touch screen operation

2) driver can manually, automatic control

主要技術參數

| 最高機械速度: | 80M/Min |

| 電氣控制: | PLC集中控制,c觸摸屏操控及監視整機工作狀態,機、電、氣一體化設計具有完備的安全保護功能,能夠智能識別整機工作狀態及判斷故障。 |

| 涂布材料: | PET、PC、PI、銅箔、鋁箔、紙張 |

| 料膜寬度: | 600~1800(MM) |

| 涂布方式: |

微凹版涂布(bu)、狹鏠(feng)涂布(bu)、網(wang)紋涂布(bu)、D棒(bang)涂布(bu)、五輥涂布(bu)、逗號輥涂布(bu) |

| 固定方式: | 熱風、紅外線、紫外線 |

| 進風流向: | 初效-主進風-中效-加熱-高效-風箱 |

| 烘箱總長度: | 3-60米 |

| 收放卷直徑: | MAX.800MM(最大卷重800KG) |

| 接片: | 自動接片 |

| 導向輥: | 鋁質導向輥 表面硬質陽極處理 |

| 鋼輥: | 鏡面,鏡面輥等級0.2 |

| 可選配置: | 真空吸易輥、儲料架、電暈處理機、除塵系統 |

| 涂布領域: | 光學膜、柔性覆銅板、太陽能背板 |